Servizi

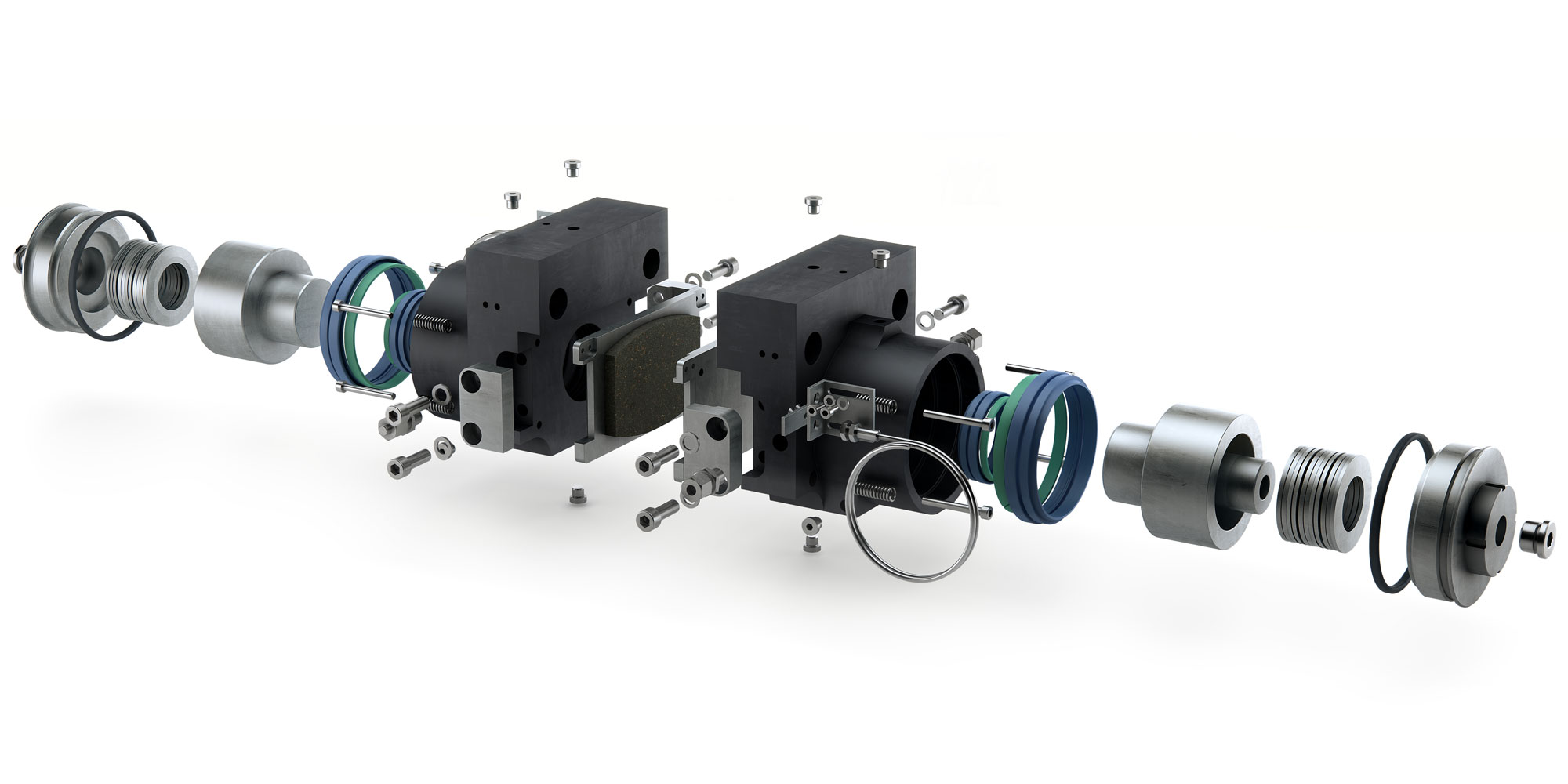

QUALITÁ E SICUREZZA NEI FRENI INDUSTRIALI

Coremo valorizza la propria esperienza nella progettazione, produzione e applicazione di freni e frizioni industriali, maturata nel corso di più di 60 anni, proponendo servizi personalizzati di consulenza e progettazione.

Coremo promuove l’innovazione costante dei propri prodotti e servizi grazie anche al supporto di professionisti esterni ed università. Una fitta rete commerciale consente una capillare presenza e vicinanza con i clienti e le loro necessità.

Velocità e qualità del servizio sono ulteriori caratteristiche distintive della società.

- Prodotti con caratteristiche di design, finitura e materiali, ottimizzate sulla specifica applicazione.

- Supporto qualificato per il dimensionamento e la scelta del prodotto. Analisi FEM (termiche, strutturali e fluidodinamiche).

- Certificazione per ambienti classificati ATEX (Ex II 2G Ex h IIC T6 Gb / Ex II 2D Ex h IIIC T85°c Db.

- Test statici e dinamici in banchi prova di proprietà, capaci di garantire le performance dei freni nelle condizioni di lavoro richieste.

- Tracciabilità del prodotto attraverso il Numero di Serie.

- Prodotti complementari a completamento dell’applicazione quali: dischi, giunti di trasmissione, centraline idrauliche (anche con pannello di controllo), moltiplicatori di pressione, staffe di fissaggio freni e sensoristica.

Supporto tecnico

Il supporto che Coremo offre ai propri clienti va sempre più verso un servizio integrato molto specializzato, che, oltre alla selezione del sistema frenante offre consulenza, manutenzione, analisi e reportistica.

Il punto di partenza, ossia il prodotto, è pensato e progettato per garantire affidabilità e certificazione rispetto ai materiali e al funzionamento, ma l’obiettivo di Coremo non è solo quello di fornire un prodotto conforme agli standard di sicurezza e alle specifiche esigenze di ogni cliente, bensì proporre un completo servizio che prenda avvio dalle informazioni che il cliente fornisce, così da ottenere una visione dettagliata delle richieste e fornire la soluzione frenante che meglio soddisfi la domanda.

Innanzitutto gli ingegneri hanno sviluppato fogli di calcolo che rispondono ai quesiti dei costruttori e dei clienti relativamente al freno, ai suoi tempi di risposta e al calore generato. I fogli di calcolo e la relazione che ne deriva sono inseriti nei report che sono inviati al cliente. La professionalità dell’Ufficio Tecnico è supportata da formazione e aggiornamento costante degli ingegneri, preparati a gestire ogni tipo di ordine e affiancare il cliente con una consulenza sia nella fase di progettazione sia in quella di manutenzione del prodotto.

L’aggiornamento è previsto anche per i software di calcolo e simulazione, sempre più sofisticati, che permettono di fornire dati sul calore generato, il raffreddamento e la resistenza meccanica per molteplici tipi di applicazione. Con l’analisi di simulazione del flusso

dei fluidi ottimizzata grazie all’utilizzo di SolidWorks Flow Simulation, si eseguono analisi fluidodinamiche in cui si evidenzia il riscaldamento del refrigerante nei freni raffreddati ad acqua.

DESIGN, CAD 2D/3D, CALCOLI, ANALISI FEM E RELAZIONI TECNICHE

Accanto alla manualistica, che include informazioni sulle forze di serraggio delle viti, sulla regolazione dei pattini e sui sistemi di sicurezza da applicare nella manutenzione ordinaria o straordinaria, Coremo Ocmea realizza disegni CAD 2D/3D, così da avere una visione immediata e intuitiva del prodotto, relativamente all’ingombro e alla geometria e della sua applicazione..

Forniture

La scelta dei fornitori di ogni componente rispecchia rigide specifiche

di progetto ed essi sono selezionati a seguito di una verifica della certificazione relativa alla precisione sulle tolleranze, finiture superficiali, resistenze meccaniche e termiche dei materiali.

I lotti sono controllati in modo costante attraverso verifiche random, così da avere certezza sul controllo di qualità.

Centri di ricerca indipendenti effettuano, inoltre, periodici controlli sulle caratteristiche meccaniche e termiche, con il fine di effettuare un confronto comparato con le dichiarazioni dei fornitori.

In generale, tutti i freni Coremo, idraulici e pneumatici, sono continuamente monitorati fin dalla materia prima alla lavorazione e assemblaggio. Il collaudo garantisce al cliente tutte le garanzie di un corretto funzionamento in base alle richieste applicative e alle specifiche condizioni ambientali.