Products

Transmission couplings

Transmission Couplings

Gear Oscillating Couplings + Elastic Couplings + Flexible Disc Couplings.

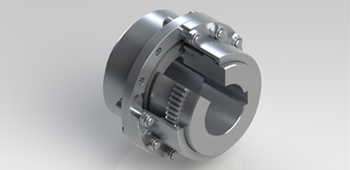

Gear Oscillating Couplings

Serie Z

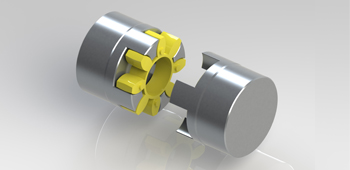

Elastic Couplings

Serie PSA

Serie PN

Serie RE

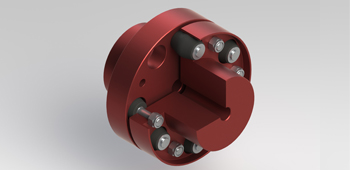

Flexible Disc Couplings

Serie FLX